Water Treatment Systems for Car Wash Facilities

Temmuz 8, 2025

What Is Sludge in Wastewater Treatment?

Temmuz 8, 2025High-Performance Treatment Solutions for Industrial and Domestic Applications

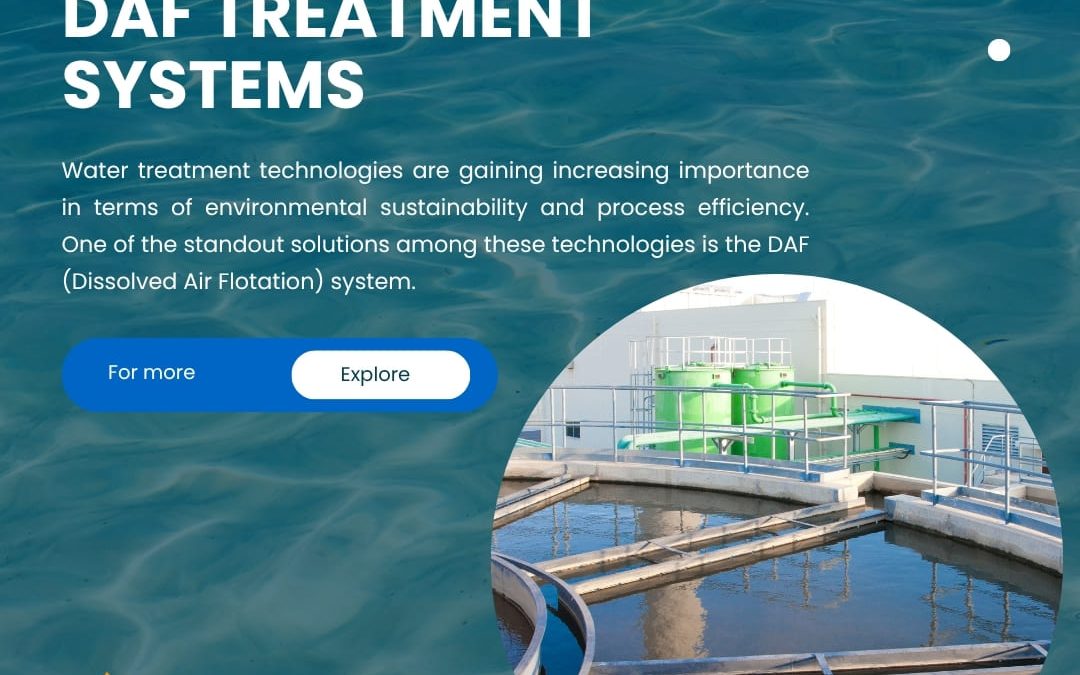

Water treatment technologies are gaining increasing importance in terms of environmental sustainability and process efficiency. One of the standout solutions among these technologies is the DAF (Dissolved Air Flotation) system.

Especially in industrial wastewater with high concentrations of oil, grease, and suspended solids (TSS), DAF systems offer an effective and economical solution.

Yeditepe Treatment & Equipment provides high-efficiency, cost-effective, and long-lasting DAF systems customized to sector-specific needs.

What Is a DAF Treatment System?

DAF systems are specialized physical treatment methods developed for separating solid-liquid or liquid-liquid mixtures in water. Dissolved Air Flotation works on the principle of saturating water with pressurized air, followed by sudden depressurization to form micro air bubbles, which then carry oils and particles to the surface for removal.

These systems are commonly used for treating oily wastewater and process water with high TSS.

How Do DAF Systems Work?

The DAF system operates in four main stages:

- Pre-treated wastewater is fed into the DAF system.

- In the air saturation unit, air is dissolved in water under pressure.

- At the tank inlet, the pressure is suddenly reduced, forming millions of micro air bubbles.

- The bubbles attach to oil, grease, and suspended particles, causing them to float.

- The foam formed on the surface is removed using skimmers, while clean water is discharged from the bottom.

Compared to conventional sedimentation systems, DAF units offer faster, more compact, and higher-efficiency results.

Advantages of DAF Treatment Systems

- Removes high levels of oil, grease, and suspended solids.

- Compact design requires less installation space.

- Low chemical consumption and low operating costs.

- Fast commissioning and processing times are ideal for industrial facilities.

- Produces less sludge; resulting sludge is denser.

- Supports automation for maximum efficiency with minimal labor.

- Applicable across many industries: food, petrochemical, textile, metal, paper, and more.

What Is the Purpose of a DAF System?

DAF is especially effective in removing oil, fine particles, fibrous residues, and chemical flocs from water. DAF systems are widely used in:

- Industrial wastewater treatment plants

- As pre-treatment before biological treatment

- Food processing facilities (meat, dairy, seafood, etc.)

- Hotels, restaurants, and other commercial facilities

- Car wash, metal plating, textile, and chemical processes

What Is a DAF Tank?

The DAF tank is one of the most critical components of the system. It houses the main treatment process. Inside the tank:

- Pressurized air-water mixture is introduced into the system,

- Air bubbles float and carry particles to the surface,

- Surface foam is removed by skimmers,

- Settled sludge at the bottom is discharged via a separate outlet.

Tank design plays a major role in process efficiency. At Yeditepe Treatment, we manufacture carbon steel or stainless steel DAF tanks tailored to project requirements.

What Is DAF Sludge or DAF Oil?

“DAF oil” typically refers to the floating layer of oil removed from the surface during the DAF process. This may contain free oil, emulsified oil, and grease. DAF systems can achieve up to 95% oil removal efficiency. The collected oil must be disposed of or, in some industries, may be recovered.

High-Performance Water Treatment Systems

DAF units can operate as standalone systems or be integrated into multi-stage water treatment lines alongside biological or chemical treatment systems. They are especially efficient in scenarios such as:

- Oil and TSS removal after chemical precipitation

- Load reduction before biological treatment

- Membrane protection before RO (reverse osmosis)

At Yeditepe Treatment & Equipment, we design optimal DAF solutions based on each project’s needs. Parameters such as coagulant selection, tank volume, scraper type, and air saturation units are custom-developed by our engineering team.

DAF systems offer fast, efficient, and economical solutions for removing oil, TSS, and similar physical pollutants. DAF technology has become a standard in industrial water treatment.

With our customized DAF solutions, Yeditepe Treatment & Equipment helps build cleaner environments, reduce operating costs, and extend the lifespan of treatment facilities.